what materials is used to make prosthetic suspension

What Materials are Normally used for Prosthetics?

The prostheses that are delivered to our clients are cleaved down into two groupings of prosthetic materials. The tiptop of a prosthesis is a custom manufactured socket which is fabricated onsite within the APC prosthetic workshop. Moving downwards on the prosthesis is the 2nd grouping of materials including structural components, prosthetic joints (i.e. hands/feet) and everyday consumables (i.eastward. liners/genu sleeves). These are ever client-specific and ordered from a diverseness of prosthetic wholesale providers effectually the globe. Read below to find out farther information on these materials used for prosthetics.

Materials used for Prosthetics

1. Prosthetic Sockets

Diagnostic Socket

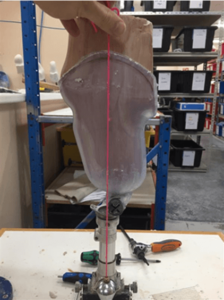

To begin the journeying of a definitive prosthesis, our clients are initially fit with a 'Diagnostic Socket' which is manufactured from their plaster bandage. The master aim of this socket is to optimise the socket fit, refine the alignment and ensure the prosthesis absolutely meets all necessary functional and comfort goals.

A diagnostic socket utilises materials in prosthetics which are suitable for a short-term trial period. These include thermoplastic sheets which are heat blistered and vacuumed onto the clients plaster cast. Following this step, the socket is attached to a lamination anchor which provides the connection between the custom-manufactured prosthetic socket and the remaining prosthetic componentry (ie. Prosthetic human foot). To ensure safe and security, the anchor is secured to the socket. This can be washed in a diversity of ways from wrapping it in a fibreglass bandage, laminating carbon fibre or fibreglass over it. Once this is achieved, the diagnostic socket is ready for a short trialling period!

A diagnostic socket utilises materials in prosthetics which are suitable for a short-term trial period. These include thermoplastic sheets which are heat blistered and vacuumed onto the clients plaster cast. Following this step, the socket is attached to a lamination anchor which provides the connection between the custom-manufactured prosthetic socket and the remaining prosthetic componentry (ie. Prosthetic human foot). To ensure safe and security, the anchor is secured to the socket. This can be washed in a diversity of ways from wrapping it in a fibreglass bandage, laminating carbon fibre or fibreglass over it. Once this is achieved, the diagnostic socket is ready for a short trialling period!

Utilising a rigid thermoplastic is beneficial in two ways. Firstly, it allows for reheating and adjustment so that pressure areas can exist relieved. Secondly, the articulate plastic allows the prosthetist to inspect the fit across the entire residual limb whilst the prosthesis is donned.

Definitive Socket

Once the prosthetic socket fit and alignment take been optimised, the diagnostic socket is 'duplicated' creating an identical plaster mould which allows our client to continue to wear their prosthesis whilst an APC technician meantime articles their 'definitive socket'. In improver, the duplication procedure allows for an identical alignment to besides be captured which streamlines the definitive plumbing equipment process and removes the need for major alignment adjustments.

The materials used for prosthetics and the definitive socket vary considerably depending on the client's presentation, suspension method and socket interface. Irrespective of these variables, all definitive sockets will undertake at least ii separate laminations, they tin can manufacture with a single lamination however 2 is more common with varying amounts of prosthetic materials.

The plaster cast will exist first either sealed with lacquer, a compressible liner, PETG or a flexible inner depending on what the prosthetist has accounted most suitable to the client. Next, a client-specific amount of carbon fibre, aramid fibre or fibreglass braid/matte is laid onto the socket and reinforced with unidirectional carbon fibre record. Information technology's so sealed under vacuum with an acrylic resin which penetrates and solidifies the material. The initial lamination is focused on creating a strong, structured framework.

Every bit the alignment has been duplicated in a jig transfer, the lamination anchor is attached in a similar procedure to diagnostic sockets. However, for the fabrication of the definitive socket, a not bad deal of detail and attention is paid to create a corrective appearance with the use of foam and putties.

The second lamination utilises similar materials to the offset, however, its focus instead shifts towards forcefulness and security of the lamination anchor to the socket. Importantly, each lamination is completely different considering every client presents slightly differently in terms of, mobility, weight and intended activities (such as running).

Specialised Sockets (Design)

Many clients opt for a specific design to finish their prosthetic sockets ranging from Indigenous Art to sports teams – there is such a diverseness! Clients are encouraged to bring in fabrics, old t-shirts or designs which they want on their last socket.

Specialised Sockets (Waterproof)

As an Island Nation with baking summers, waterproof prostheses are essential! The lamination process is largely similar; however, it includes two additional laminations to finish with a cosmetic advent which reflects the sound side limb. The APC technician precisely shapes foam around the socket co-ordinate to the client's measurements. This process removes the need for standard tube clamps and pylons which rust in water-based environments.

Specialised Sockets (Cosmetic Finish)

Similarly, to a waterproof prosthesis, a corrective stop utilises a foam which is shaped by an APC technician co-ordinate to client measurements. Tracings of the sound side limb tin can be taken to ensure the prosthesis is as aesthetically appeasing every bit possible.

Specialised Sockets (Recreational)

The initiation of the National Inability Insurance Scheme (NDIS) has allowed many clients the opportunity to explore a recreational prosthesis such as running blades, rock climbing arms/legs, weight-lifting artillery, surfing legs, cycling legs and many more. The custom design and materials used in prosthetics, let for many recreational prostheses to be achieved.

Final and definitive prostheses reverberate the nifty bargain of detailed hours undertaken by both the prosthetist and technician to create custom-manufactured prosthetic sockets.

2. Prosthetic Componentry

Underneath the prosthetic socket is the second grouping of prosthetic materials – componentry. These are manufactured on a large scale by prosthetic wholesale companies across the earth producing materials in prosthetics such equally anxiety/easily, connective componentry, pins/locks, valves, pylons, adaptors, liners etc.

Importantly, despite being mass-produced, the prosthetist orders componentry which specifically meet a customer's presentation, goals and intended activity. For instance, one prosthetic foot may entail up to 10 different weight categories, it's essential to obtain the current category for the client to ensure the best possible consequence.

I. Anxiety

- Wood, plastic, and foam are unremarkably materials used in prosthetic anxiety designed for individuals who have low action levels and require stability

- Carbon fibre feet is besides one of the materials used in prosthetic feet designed to come across ane'south functional needs for shock assimilation and energy efficiency

II. Connective Componentry

- Aluminium, stainless steel, carbon and titanium are materials used in prosthetic connective componentry.

- Standard adapters are used to build the prosthesis, connecting the socket to a prosthetic joint and/or to a terminal device/foot.

- Functional adapters such as torsion and rotation adapters assistance make every day and/or recreational activities easier for patients past expanding the abilities of their prostheses.

For more information on materials used for prosthetics please go far contact with the team below!

Source: https://apcprosthetics.com.au/what-materials-are-commonly-used-for-prosthetics/

0 Response to "what materials is used to make prosthetic suspension"

Postar um comentário